Operating beyond nationally accepted standards and stringent customer approvals to deliver exceptional service to challenging industries. Our knowledge and expertise in non-destructive evaluation is held in high regard in a number of industry sectors. We specialise in testing bars, forgings, castings, and fabrications. Materials including ferritic, austenitic, duplex, nickel-based alloys, copper alloys, brasses, bronzes, aluminium, and titanium. All our work is carried out in accordance with ISO 9001:2015 and specific customer accreditations.

Used primarily for the detection of defects and flaws and to measure material thickness, we use the latest digital technology whether we are carrying out in-house inspections, out on-site or at a customer’s premises. We use ultrasonic testing to test anything from small components and bars to large castings and forgings.

We pride ourselves on the quality of our service, so all our operators are qualified to SNT-TC-1A and PCN (ISO 9712) Level 2 standards and capable of delivering Level 3 services.

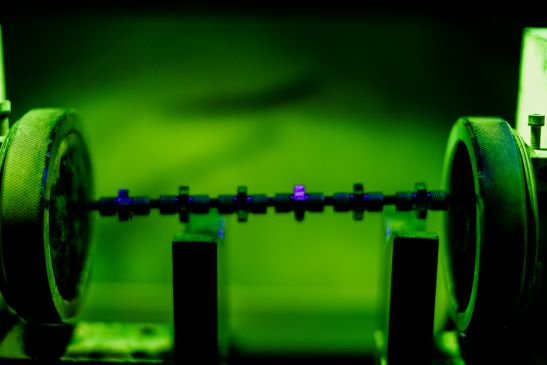

We are able to deliver visible and fluorescent MPI services in-house, on-site and at our clients’ premises for the detection of surface or near surface defects in components both small and large. We use 2,000A and 3,000A bench units for inspecting small to medium sized components and the more powerful 5,000A unit for testing large components. Our facilities have the capability to test components up to 6,000mm in length.

We use both visible and fluorescent LPI techniques for the detection of surface breaking flaws in a range of components, and are able to perform single component inspection or carry out batch component processing.

The equipment we use makes it possible to perform inspection in-house, on-site or at our clients’ premises.

Qualified visual inspection carried out as part of manufacturing process plans. The equipment we use makes it possible to perform inspection in-house, on-site or at our clients’ premises.

Positive Material Identification (PMI) is the quick and reliable analysis of metallic alloys to establish their composition by reading the quantities by percentage of constituent elements. Methods available for PMI include X-ray fluorescence (XRF) and optical emission spectrometry (OES) and can be performed in-house, on-site or at our clients’ premises.

STW (Non-Destructive) operate a quality management system in accordance with BS EN ISO 9001:2015. This ensures customer confidence in our competence, impartiality and reliability when providing inspection results. Our attention to quality and service is recognised and respected throughout the industry.

We offer level 3 services for:

All work is performed to fully documented procedures, which dictate the normal standards to which we work. These procedures have been developed to conform to the following internationally recognisable standards:

These procedural standards form the basis of our Quality Management System, and through this we aim to continually enhance our reputation within the industry for providing non-destructive testing services of the highest quality to our customers.